New tool.

Man, don't you love a

new tool?

Over the course of many years and many restoration type projects one of my

favored but messy tools has

been my home sand blaster. You've seen them. Small sand hopper

with a screen cover on top. Twenty feet of feed hose connected to a

small gun with replacement tips, (when needed). The sand blows nice

and even and pits the working surface so nice and clean! Rust and

old paint all but disappear before your very eyes. Once I realized how cool a blaster

was and how cheap and small my existing air compressor was, it didn't take me long to go out and buy me a

new high volume air compressor. Oh ya! This was cool and it

worked great! The days of sore fingers and cut knuckles from hand sanding,

scraping and wire brushing were gone! Old parts and old tools looked brand new

again after a light blasting! Better than new in some cases. Once a part was blasted, just air off the

excess dust

and spray paint it right away. The fresh porous surface takes

paint and holds it fast for the best finish I have ever seen.

For years I've been messing up the side yard, spending money on sand,

and getting it absolutely everywhere. In my shirt, down my pants, in my hair, and down my

pants, in my ears, and down my pants. Ok,

the sand is kind of a pain in the butt, (sand actually in my butt).

Sometimes when running low on sand I would sweep up some of the excess sand from the ground and filter it back in to the hopper

to be reused. This would blow dirt and cause clogs. Bad idea. I

was always going to build a sandblasting cabinet some day.

Something to contain all the mess and funnel sand back down to

the hopper for reuse. I never made one that lasted or worked

well. One day I vowed I would have a proper sand blasting cabinet.

Time marches on.

|

Well now I have the biggest project I have ever

had in my whole life. Other than raising a family. "The

River Queen Refit" This boat, being made from steel is just

chuck full of things that could use a good sand blasting including the whole outside and

underneath! I did end up blasting the

bottom and sides when we were hauled out but I used a blaster the

size of an African anaconda and had to hang on for dear life and limb. I know it's simple in

principle but

it sure seems like magic when you see stuff fall away as you wave

your tool and bare metal remains in its' wake. To my dismay thin spots will

blow through and leave a hole. It's just as well to know where all the thin

spots are anyway so we can fix them! But does there have to be so damn many? |

It's

harder than it looks. Then add 100+ temps! |

When good parts go bad.

If it's marine, it's expensive. If it's

expensive, I try to fix it first, not replace it. But if you fix it, you damn

well better fix it right or you can't trust it. It's of no good use to you if you

can't trust it. Due to my tight budget I never replace anything

that I haven't tried to repair or rebuild first. Granted, there are some things you just

don't

fool around with and should always buy new, like safety equipment, bilge and fuel pumps and head valves. Add engine room blowers and gas

fittings to the list as well. Better safe than sorry. For some reason, probably the

moisture, things on a boat get

"crusty" yep. Covered with rust, film, crud, shit and

piss, you name it. Now, if I were a wealthy man, (dream on), I would just toss

any part that didn't pass muster right in the old dumpster and flip

open my favorite book "West Marine Catalog" and order

up! Hell with the cost. (God I wish). Here in the real world the part in question carefully rides home with me in the truck and

goes to the bench for a few snap shots and illustrated notes. ( Tip- Always take

snap shots and illustrated notes). The next

thing we do is (and you do this too! admit it) is run down to the

local hardware store and look for a reasonable replacement or facsimile.

Almost always to

no avail. Sometimes we feel we need to ask for help from one of

the store clerks, and we seek out the oldest and most wisest looking

gent in the store. In my case they know me on sight and hide behind something. When we

finally find just the right person he'll "hmmm" and ask one or two questions. "What's

it for?" (Same reaction for the auto parts store person as

well). There are two words that will cause this person to stop dead in there tracks,

give you an insulting look, make an excuse and head in the opposite direction.

They are "Boat" and/or "Marine". After

wasting all that time and energy you head back to the work bench and reevaluate the part in question. We might even look up the part

in that damned catalog again, but the price is still the same.

"Too damn much!" I guess I'll just have to fix the damn

thing myself. That's what I'll do... "To hell with those guys! Remember, "It's a

hobby" enjoy the challenge of it.

This dose that.

You ever bring a machine or part back from the

dead? Very satisfying isn't it? I love it. I don't know where I get it from but

I hope to pass it on to my kids. I think it may stem from when I was ten or so.

My dad would bring home things for me to take apart. Not fix or put back together, just

tear apart. He would provide me with several empty coffee cans and a bag of

tools and say. "Screws this can, nuts and bolts, that can, electrical switches and

connecters..." Well you get what I mean. He

would bring me a wide assortment of things. Clocks, blowers and relays. One item

still remember was an old cigarette

machine. You know, I think dad still has the knobs to that old thing in

one of his many drawers of spare parts. My dad is a man of few words. He wasn't using me to

help him get spare parts, though I'm sure it was a plus to him. It was more of a

self taught lesson in how things work. What's inside, and what tool to use to

take it apart. Over the years I would learn to see things for their parts therein and not the whole unit. My first

lesson in "back together again"

was a two horse Brigs and Straiten lawn mower engine. We took that thing all the

way down to its' smallest component. Cleaned it. Oiled it. Hand cut new gaskets.

Hand lapped the valves. Made every small part the best it could be, and put it

all back together again. To my proud shock and amazement, it started first

pull. In doing this, I was able to see first hand the logic of the machine. The

"this does that." and so on. The magic of the machine was revealed to

me. To a good number of people today it is still vary much magic. To my

sons I now teach this magic. I bring junk home to be dismantled as often as possible. Now I have a bigger collection of knobs then my father.

My second "together again" project was a motorcycle.

Oooh! ahh! I was fourteen or fifteen years old and it was a nineteen fifty something

Benelli 350cc street bike. Basket case. All in parts in box's. I was

told by I don't remember who that the Benelli was sold by Montgomery Wards as a

catalog item imported from Italy. My dad and I had a real puzzle on our hands in

that old Italian thing. The foot breaks and gear shifts were on opposite sides

then that of a American bike. In time we got it all back together somewhat but found that a small part in the kick starter was

damaged beyond repair. A machined part. After what was an eternity to a fifteen year old,

we found ourselves in the old "Niles Cycle Salvage" store.

I remember my dad holding up the old part. About an inch in length. to show the

rather rotund and hairy guy in greasy old coveralls the part needed and what it

went to. After going to almost all the other shops in a twenty mile area we were

expecting the "Never seen that before" we heard so many times before.

This guy hmmm'd at it and reached over into a old salad bowl full of little odd

parts, fished around for a second or two and produced an identical copy of the

part needed. In perfect condition. I about fell over. My dad cracked one of his rare

smiles and said "How much?" I thought this guy new he had us by

the balls! I thought for sure he was going to gig us like a frogs in a pond. He flipped

the little part to me and said "Ah, take it" Dad made him take

two bucks for it but I knew that he knew it was worth way more than that. I

think the real price for that part was the smile he saw on my face, and knowing

that this kid was going to get the first real thrill of his life by getting a

ride on his first big bike. Well we should have paid him double because it was

my dad's first time on a big bike too.

|

|

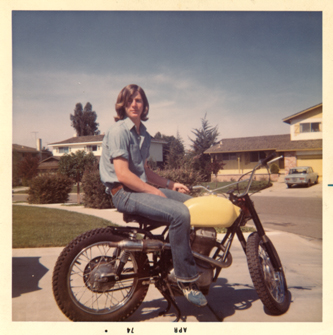

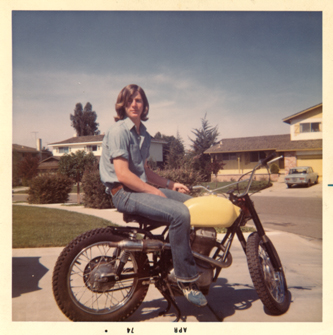

That's me all right!

In 1974 I was a junior in high

school.

This old bike had some real torque

man. A one lung 350cc that could stand on one tire any time I wanted... |

I digress...

"My new

tool!"

About a month ago I finally got my blast cabinet. Used, rusted

and run down....of course..... but definitely a nice one, and....of course.... like anything I

get my hands, on was properly torn down (including snapshots and illustrated

notes). Cleaned, painted and pampered, back into first class shape. This

was the easy part. The problem now lies in my once new air compressor you read

about earlier. I'm not complaining mind you. This now old pressure unit has

served me well for well over 25 years with hardly any service at all. (I'm bad

about that). If I didn't do some preventative maintenance on it and soon, it

would get ruined for sure. One compressor tear down coming up.

In the condition it was in, I could not believe this old

girl could still work at all...I was lucky, even though the oil was low and

looked like mud. The reed valves in the head looked like (searching of a word

here) well they looked like shit. I was able to recondition all the parts

and get it all back together again, (and work) And work good it does. I'm

sure I was able to return it back to say 99% of it's original output and recover

capabilities. Hell I think it runs and sounds better than it ever has! But I

tell you what, I been running the piss out of her since we been back online.

Hope she holds up.

|

It's a blast!

No really "A blast" This new blasting cabinet

is real cool. Notice I didn't call it a "Sand blaster." Well it is in

a way but as I found out, sand isn't the only medium you can put in them. On the

label it says "Blast and Peening Cabinet"

"What the hell is this peening thing?" Peening I'm

told is like steel shot. Small ball bearings. When you lightly hammer on the

outside of a part you condense the surface molecules make that surface a little

bit stronger. When you shoot small steel balls under pressure on a surface it's

like hitting it with a bunch of little hammers making it stronger. It makes the

surface look more finished as well as making it stronger by pounding down and

rounding over the rough spots and deburring sharp edges.

|

My new blaster.

|

Blasting medium differs widely as well as the grit size. I

know of sand, rock, glass beads and walnut shell. Yep, walnut shell. Good for

removing unwanted paint but not the metal. Each different material with its' own

blasting characteristic and will come in as many ten or more sizes. From a rough

coarse size to powder so fine you would think it was dust. Currently I'm using a

fine glass bead (#5) This would explain the big vacuum units that come with

these blasting cabinets. The glass bead can remove rust and discoloration in

hard steel. It really puts new life back into the old tools that look bad and

cut through the crusty crap when inspecting for cracks in parts. The pattern for

me has been - Blast, inspect, repair, refinish (File) re-blast, air off, paint.

Done deal.

I love this stuff...

Back to

the...

River

Queen Refit index