13-Jan-2016

13-Jan-2016Mike Wolfe Chapter Nine "The River Queen Refit" 2005

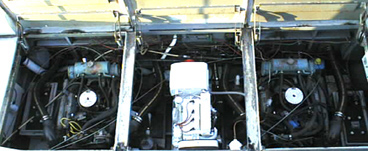

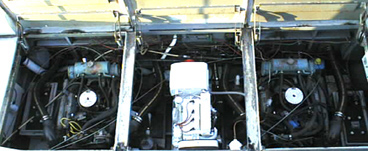

Engines

13-Jan-2016

13-Jan-2016

Engines are the most complex and important system on the whole boat. Well ok, the hull is the most important system. But right next to that is indeed the primary drive engine. The difference between making it home safely or not! When you lie on your bed at night letting your mind race along for some reason you keep thinking , dwelling on the possibility of a slow leak leading to the ultimate sinking of your pride and joy. But when your in swift current and coming about with other boats around, or you're a good 10 miles out and you're thinking of home port you don't want to brake or lose your engine! The "drifting toward the rocks," "Oh Shit!" kind of feeling. God I hate that one!

Keep a raft.

A brief history of my engines.

I was told by the previous owner that it had been 6 years since the engines had been started. Just sitting there as a live aboard. Well , it was time to roll up my sleeves and dive in. Before you can make a boat your own you got to get all the "other people's stuff" off. We gave her a scrub down and she looked even better with white paint showing through the peat dust. Now was the time to do a safety check and try to get the engines to fire. We had about two weeks 'til the end of the month to get the engines to fire and get her ready to move to the haul-out yard. First of all... the old batteries (2) had to go! They looked very sad indeed. Actually they looked dangerous. The kind that you wonder if the suckers will break into pieces while trying to extract them... The old wet exhaust hoses were old, over-heated looking and duct-taped in spots. Nothing that 20 feet of new 3" wet exhaust can't fix. But low and behold...My first "Oh, Crap!" of many oh-Craps to come. One of the exhaust elbows was way gone, and the rest not too good looking. A major cost hit early in the budget and my first opportunity to absolutely ruin my manicure. But in relatively short order and with the help of some good buds and some cold Buds we got the new ones wrestled into place. This is all before we could even start the engines. I still had never heard the engines turn over yet and before we could even try we needed to chase out the mess of wires and starter cables, some of which had melted spots! Without replacing anything and with the use of some electrical tape Daryl and I straightened out most of the mess to the point of making an attempt at turning them over. With my heart pounding in anticipation of anything that may happen, Darryl said "Number one, Hit it!" and we were rewarded with a happy "rrr rrr rrr" "OK" says Del "Number two, Hit it!" "Click" That's all we got. Just the "Click" from the cellinoid. With hammer in hand Darryl sent me down in to tap the starter to free it up. I looked and looked, this side and that, and back again, and...where is the starter? No starter! Just a hole where one should be. As sad as it was we shared in a good laugh at our folly and finished off the last of the beer. We would be making the trip to haul-out without the help of number two engine.

All along the fore side of the engine compartment we have three stainless steel 90 gal. fuel tanks, all of which have some, but not very much, rather old gas. Number 1 tank (port side) was the one that was most empty. About one inch off the bottom of the tank. I mixed in some booster and stabilizer with about 22 gal of new gas and plumbed it into a electric fuel pump and ran it 'til we got nice clear gas out of it. Quite a lot of gunk came out! Due to the long time between startups, buddy Daryl said it was absolutely necessary to split open the carb and look into the floats. Without hesitation and with great skill Deller opened #1 carb up with Carl to assist. What a crap-load we found inside! (Good call, Del!) But in short order and two or three beers later the mess was cleaned up to an acceptable level with the promise of a rebuild kit in the future. Some more time was spent on plumbing in a makeshift fuel line as most of the existing copper had been removed for some unknown reason. Then it was time to fire it up! Once again it was time for the ol' heart to start pumping again. Okay, it's no biggie for some people but I was excited, as well as Darryl and Carl. I still had no idea if the engine was broken inside or froze up, and after spending a good deal of time, money and sweat working on the exhaust and electrical. Well, after some pumping and cranking, she fired and seemed O.K. Except for the ticking of what we think is hung lifter. Well, it would have to do, to get us to haul-out.

From October to January was kind of a blur... In this cold season and in my recovery mode from some emergency surgery I had to have I spent most of my time out in the garage working on the genset project. Haul out was heading to a close and once again to the rescue came Carl, Daryl and Pat to help me get the engines so they will start and stop. This is necessary to get the boat to home dock 300 yards away. This included carb kits x 2. Plugs x 16. Oil, coolant, sweat, blood, beer, cables and lots, lots more. Oh, and a new used starter for # 2 engine.

Finally on a cold January afternoon with a bad cross-wind from the north-west we ventured forth. All seemed ok til I went for reverse to slow down and both outdrives popped up! Then I lost #1 engine and with it my power steering. "Oh, geeze!" Well I was lined up ok and came in on the money. (Remember the crosswind) It did not seem to me that we were going that fast... Bang! Scraaaatch! And we were in our new side tie.

Some time and of course some money was spent in preparation for our first run. #1 engine seemed ready. Not much more could be done to it short of a rebuild. It still had a tic, tic, tic. We decided it was a hung lifter and it didn't seem like it would free up any time soon. The idea here was to run #1 'til something happened to it. The tic sound may loosen up and go away. #2 engine was the sweet heart of the two. Easy to start and it purred nicely. Two days before what was intended as a first run target date we started getting a higher RPM pop or misfire. It was solved by installing points, rotor, cap and wires.

Heading home from our first overnighter. Clouds of water vapor spewed from #2 engine Vent. Luckily, chance had provided us with an open dock along the waterway just 100 yards off our starboard bow. We opened the aft engine hatch to assess the problem. Our #2 engine's water pump had lost it's pulley retention clip, and so the belt had slipped off of it. We tried to find the clip, but it was lost in the bowels of the ship. We improvised another clip from a coat hangar! We once again cast off and soon were tying up at our home base.

Now were at the point of time to yank out #1. Cause #2 sounds like crap now. It seemed ok for this season till I thought I'd be smart and put in a can of engine clean in it. You kn ow the one. Smells like and probley is mostly diesel fuel. Well after that it tics really bad now... Damn...

So let's assess the engines as they sit.

#1 Engine.

Runs, No oil pressure.(not froze) Bad tick sound. smoking right bank.

Not useable.

#2 Engine.

Runs. Ticks, Smokes. Power steering unit works.

Barely useable.

At this time both engines were looking vary sad indeed.

Back to the main River Queen Refit page.